A Better Built Body

Our DuraPlate utility truck bodies are designed to provide maximum capacity and corrosion resistance, while providing a smooth exterior that’s perfect for graphics

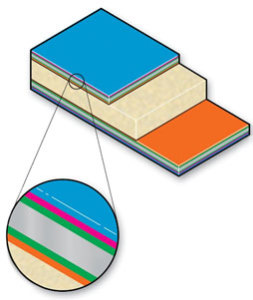

DuraPlate® is durable material that is commonly used in construction of semi-trailers. The panel is constructed of a high-density polyethylene (HDPE) core, bonded between two sheets of pre-coated galvanized steel skins. These materials produce a composite panel that is extremely strong, lightweight, and damage resistant.

Stainless Steel Rear Frame

A 12 gauge stainless steel rear frame comes standard on all truck bodies. All corners are internally reinforced for strength, as well as externally gusseted at the top corners. This frame will look good throughout the life of the body. No need to worry about chipping paint or corrosion.

One Of A Kind Roof

Our unique two-piece roof-rail design not only increases strength, it also means the roof can be easily replaced (if damaged) without disturbing the sidewall structure. Durable, aluminum castings on each corner increase strength while front “zephyr” improves aerodynamics.

LED Clearance Lights

Brighter, longer lasting LED clearance lights are standard and are FMVSS-108 compliant. LED tail lights are also standard with the recessed taillight option.

DuraPlate Swing Doors

Our swing doors are an industry benchmark. We custom build each door using 13mm thick DuraPlate® panels solely for toughness and durability. Stainless steel bar lock hardware, aluminum hinges, and replaceable stainless steel pins are then installed creating an extremely strong door that’s corrosion resistant.

Corrosion Resistant Hardware

The swing doors are not the only part of the truck body with corrosion resistant hardware – the exterior is assembled using aluminum and stainless hardware.

Domestic Hardwood Floors

We use only 1-1/8” or thicker laminated domestic hardwood, which run the full length of the truck body, to ensure durability. No need to worry about delamination or warping down the road.